If your extractor fan has stopped working, you’re not alone. In Brisbane’s humid climate, a broken extractor fan isn’t just annoying-it can lead to mold, mildew, and poor indoor air quality. The good news? Most extractor fan problems are simple to fix yourself, without calling a technician. You don’t need special tools or electrical training. Just a little patience and the right steps.

First, check if it’s really broken

Before you start taking things apart, make sure the fan isn’t just stuck or blocked. Sometimes the issue isn’t the motor-it’s just grease, dust, or a plastic bag caught in the blades. Turn off the power at the circuit breaker. Then, remove the cover and look inside. If you see thick layers of grease, sticky dust, or debris, that’s probably your culprit. Clean it with warm soapy water and a soft brush. Let it dry completely before reassembling. Turn the power back on and test it. If it runs now, you’re done.Check the power supply

If cleaning didn’t help, the next step is power. Many extractor fans are wired to a light switch or a pull cord. Make sure the switch is turned on. Try flipping it off and on a few times. If the fan is controlled by a timer or humidity sensor, those can fail too. Test the fan by bypassing the switch-connect the live and neutral wires directly (only if you know how to do this safely). If the fan spins when you do this, the problem is in the switch or sensor, not the motor.Listen for humming

If you turn the fan on and hear a low hum but no movement, the motor is getting power but can’t turn. This usually means the capacitor is dead. Extractor fans use a small capacitor to give the motor that initial kick. Over time, these dry out-especially in hot, steamy bathrooms. A bad capacitor won’t make the fan stop completely; it’ll just sit there buzzing. You can buy a replacement capacitor for under $10 at any hardware store. Match the voltage and microfarad (µF) rating on the old one. Disconnect power, remove the old capacitor (it’s usually a small cylindrical component with two wires), and swap it in. Soldering isn’t always needed-many just clip into place.Inspect the blades and bearings

Even if the motor runs, the fan might not spin if the blades are seized. Over time, moisture and grease build up around the shaft, locking it in place. Try spinning the blades by hand. If they don’t turn freely, the bearings are clogged. Use a few drops of light machine oil (like 3-in-1 or sewing machine oil) on the shaft. Don’t use WD-40-it’s a cleaner, not a lubricant. Let it sit for 10 minutes, then try turning it again. If it still won’t move, the motor may be worn out.

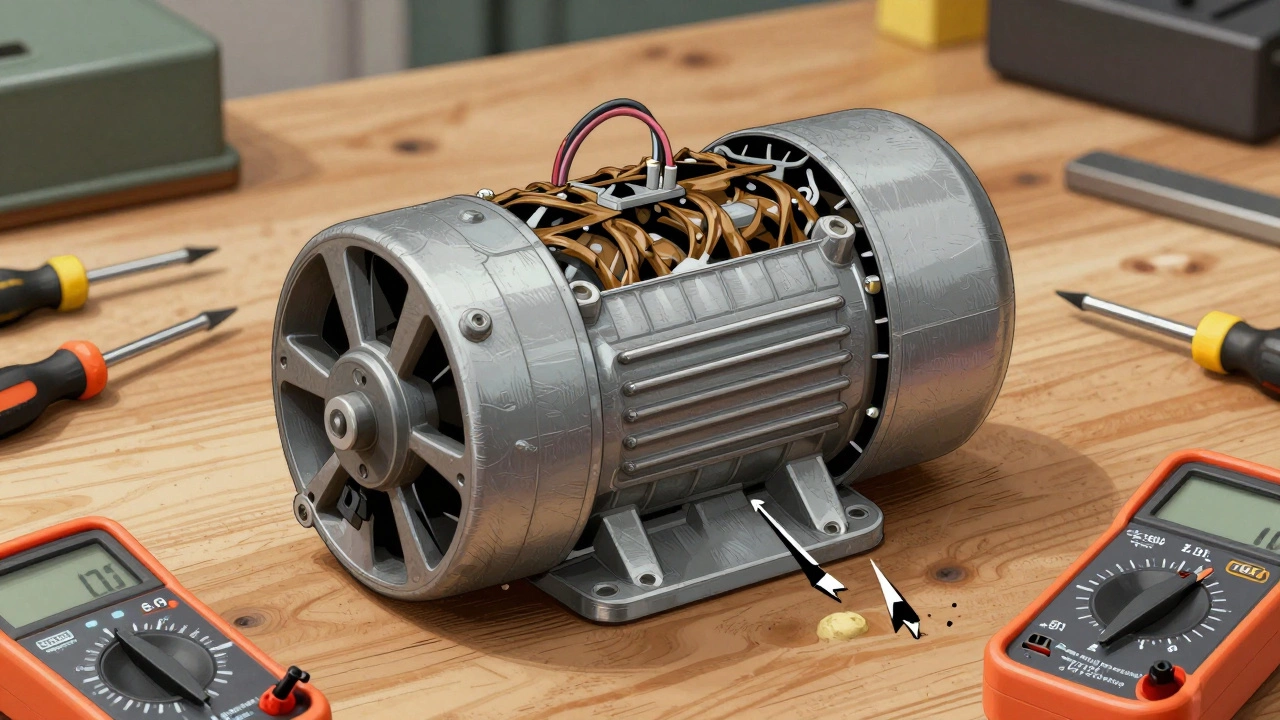

Test the motor

If the fan doesn’t hum at all and doesn’t spin, the motor might be dead. You can test it with a multimeter. Set it to ohms (Ω). Touch the probes to the two motor terminals. If you get a reading between 5 and 50 ohms, the motor winding is intact. If it shows infinite resistance (OL), the motor is burnt out. If you don’t have a multimeter, try gently tapping the motor housing with a rubber mallet while the power is on (only if you’re comfortable doing this). Sometimes a stuck armature will free up with a light tap. If that doesn’t work, and you’ve ruled out the capacitor and switch, the motor needs replacing.Replacing the motor or whole unit

Most extractor fans are designed to be replaced as a unit, not repaired. If the motor is dead, it’s often cheaper and easier to swap the whole fan than to source a compatible motor. Take the old unit out-note the size (usually 100mm, 125mm, or 150mm), the airflow rating (in litres per second), and whether it’s ducted or recirculating. Buy a direct replacement from a local supplier like Bunnings or Mitre 10. Look for models with a built-in timer or humidity sensor if your old one had one. Installation takes under an hour. Turn off the power, disconnect the wires, remove the screws, pull out the old unit, feed the wires through the new one, secure it, reconnect the wires, and test.Prevent future breakdowns

Once it’s fixed, keep it running smoothly. Clean the filter and blades every three months, especially in kitchens. Use a vacuum with a brush attachment to pull out dust from the ducting. If you have a recirculating fan, replace the charcoal filter every six months. Avoid painting over the fan cover-it traps heat. And don’t ignore strange noises. A squeak or rattle early on can save you from a full motor failure later.

When to call a professional

You don’t need an electrician for most extractor fan repairs. But if you’re unsure about wiring, if the circuit breaker trips when you turn it on, or if the fan is connected to a complex ventilation system, stop. Faulty wiring in bathrooms can be dangerous. If you smell burning plastic or see melted insulation, turn off the power and call a licensed electrician. Same if the fan is part of a whole-house ventilation system-those require proper airflow balancing that’s beyond DIY.Common mistakes to avoid

- Using WD-40 to lubricate the motor shaft-it dries out and attracts more dust.

- Ignoring the capacitor-most people assume the motor is dead when it’s just the capacitor.

- Forgetting to turn off the power at the breaker-never just flip the wall switch.

- Buying the wrong size fan-measure the hole in the ceiling or wall before you shop.

- Reinstalling the fan without sealing the edges-air leaks reduce efficiency and let moisture into the ceiling cavity.

What to look for when buying a new extractor fan

- Airflow: Look for at least 15 litres per second (L/s) for bathrooms, 20+ L/s for kitchens.

- Noise level: Choose one rated under 40 decibels-quieter than a library.

- Energy rating: Go for a 4-star or higher model-modern fans use less power.

- Features: Timer, humidity sensor, and reverse flow valve (stops air from coming back in) are worth the extra cost.

- Brand: Brands like Vent-Axia, extractors from Panasonic, and Elica are reliable and widely supported in Australia.

Most new extractor fans come with a 2-year warranty. If you’re replacing an old unit, this is a good time to upgrade. A modern fan will save you money on energy bills and keep your home drier and healthier.